Surface-engineered textiles designed for hygiene-sensitive and close-to-skin applications.

HTX antibacterial metal-coated fabrics are functional textile platforms engineered for hygiene control in close-to-skin environments. By applying a controlled metal-based surface treatment at the material level, these fabrics are designed to help reduce odor-causing bacteria and support cleaner wear conditions over time.

The treatment is engineered to integrate with the textile surface without altering the intended structure, comfort, or wear behavior of the base fabric.

HTX antibacterial fabrics are offered as standardized material platforms defined by surface treatment parameters and performance behavior.

Material supply is independent of equipment sales.

Manufacturing may be performed on HTX internal lines or through qualified partners operating under controlled process conditions. Materials are delivered in formats suitable for downstream cutting, sewing, or lamination, depending on application needs.

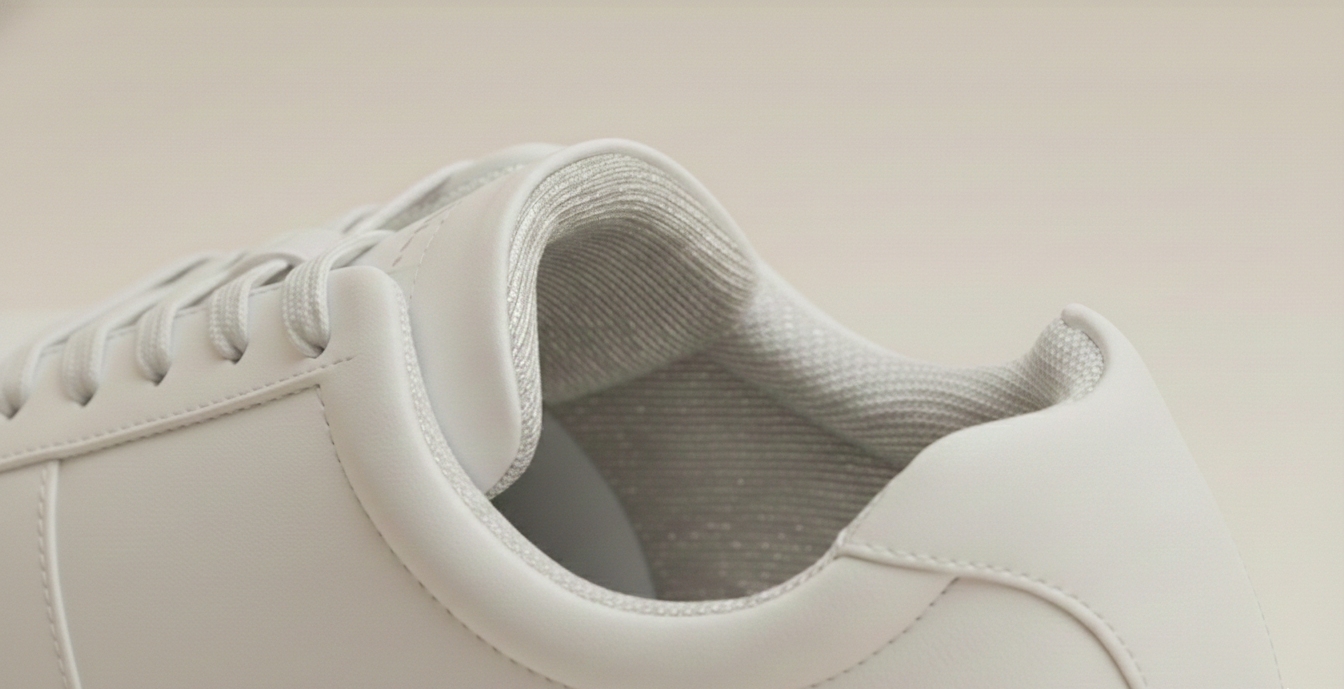

Antibacterial performance has been evaluated using multiple internationally recognized test methods, reflecting different contact conditions and evaluation perspectives. The results below summarize representative outcomes from independent laboratory testing.

This method evaluates antibacterial activity under dynamic contact conditions, simulating movement, agitation, and repeated interaction. Relevant for wearable applications where fabrics experience motion and friction.

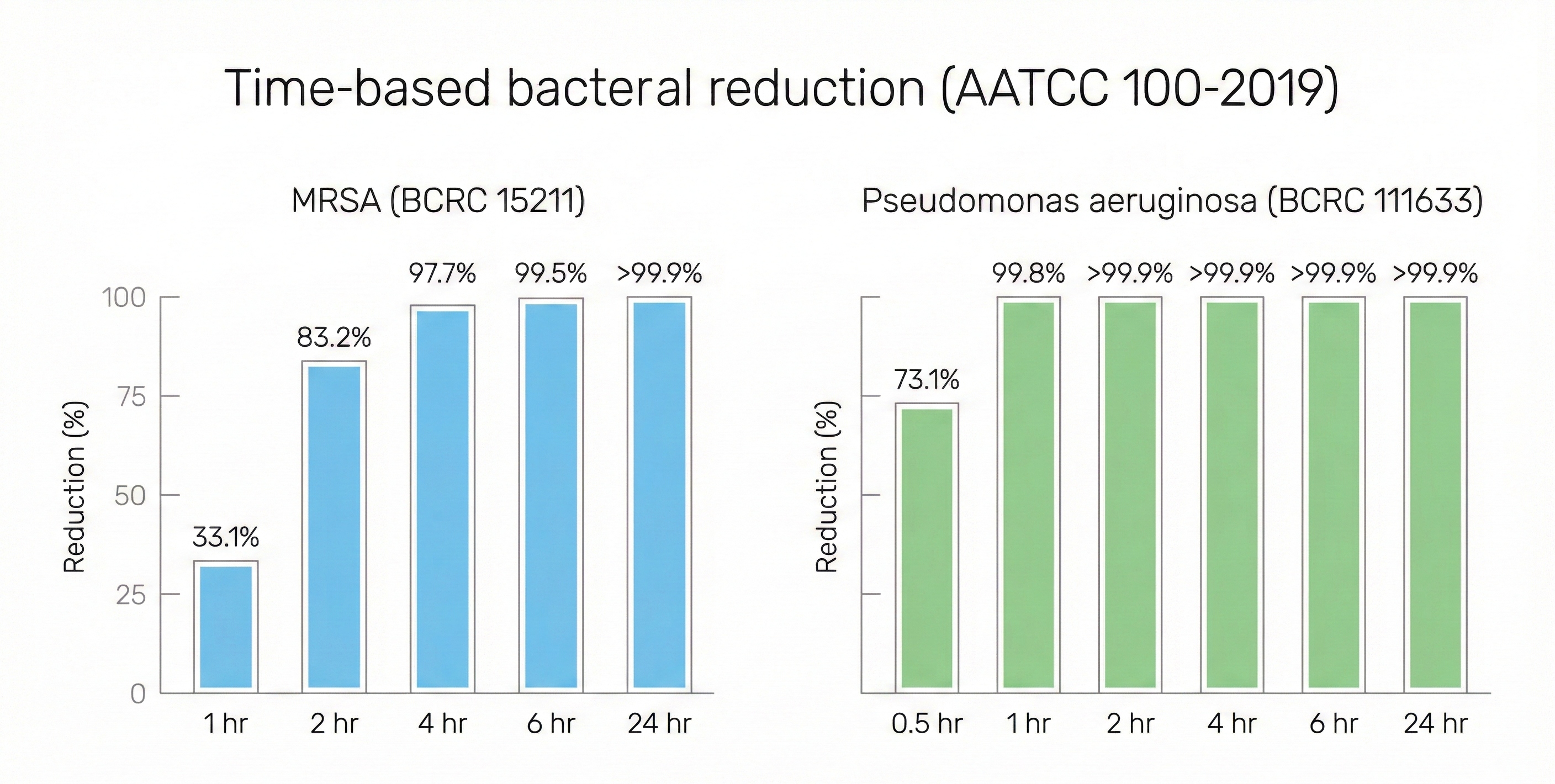

Evaluates antibacterial effectiveness based on controlled contact time. Provides a time-dependent view of behavior under static conditions.

MRSA (BCRC 15211)

| 1 hr | 33.1% |

| 6 hr | 99.5% |

| 24 hr | >99.9% |

The two test methods represent different usage perspectives. ASTM E2149-20 reflects antibacterial behavior under dynamic, real-world movement conditions, while AATCC 100 (2019) illustrates how effectiveness develops over time.

HTX-47 is the standard material reference used for antibacterial applications.

It represents a silver-based functional surface designed for hygiene-related and close-to-skin use.

For antibacterial material platforms, HTX provides optional material identification tools to support clear and consistent downstream communication. Antibacterial performance is defined at the material level and referenced using standardized HTX material codes.

The identification tag does not function as branding or certification. It serves as a material reference, allowing partners to explain antibacterial behavior accurately without disclosing proprietary process details.

Material identification tools are optional and application-specific. They are provided to support transparency and material education — not to dictate product branding or marketing language.

We welcome discussions to evaluate material suitability for your specific application.

Email HTX MaterialsIf possible, please include: