Engineered for long-term operational stability. Precision coating, automation, and scalable R2R processes.

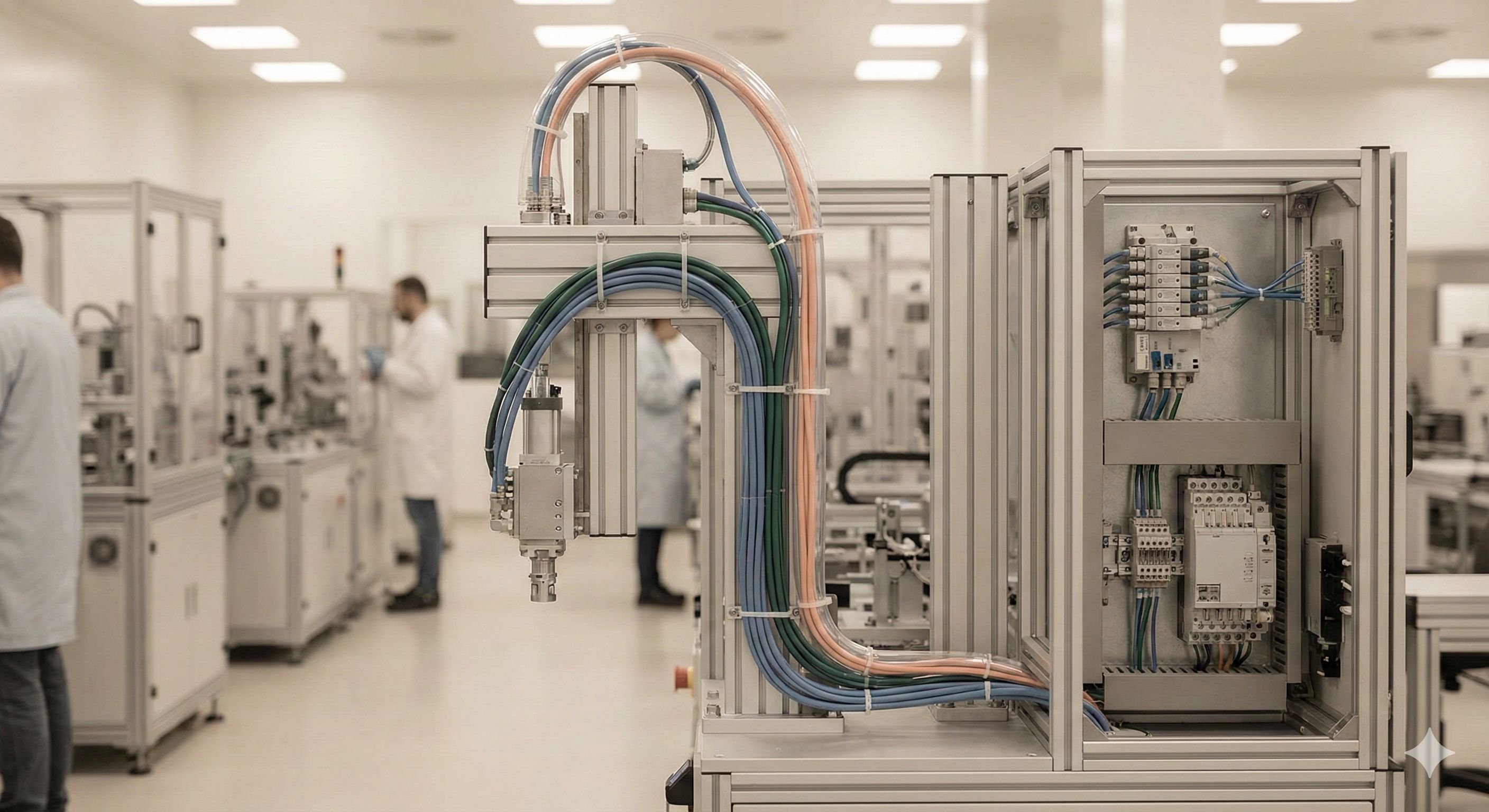

HTX systems are manufacturing-oriented platforms developed for vacuum-based surface engineering. Each system is engineered to support stable long-term operation, controlled coating behavior, and scalable production deployment across industrial environments. Systems are delivered as integrated platforms rather than isolated machines, with architecture defined by process requirements, operational reliability, and future expandability.

HTX defines system architectures, process stability criteria, and operational parameters for all systems delivered. System development may be executed on HTX internal platforms or in collaboration with qualified manufacturing partners under controlled engineering standards.

Systems are supplied as production-capable engineering platforms, independent of material supply programs.

Process validation and optimization are conducted through structured technical collaboration prior to scale-up.

Focus on precision fiber handling and controlled deposition behavior. Ensuring uniform coating thickness on continuous filaments.

Wide-format transport stability designed for long-run operation. Optimized tension control for delicate substrates.

Thick-film, multi-layered coating systems engineered for heat management and high-temperature industrial applications.

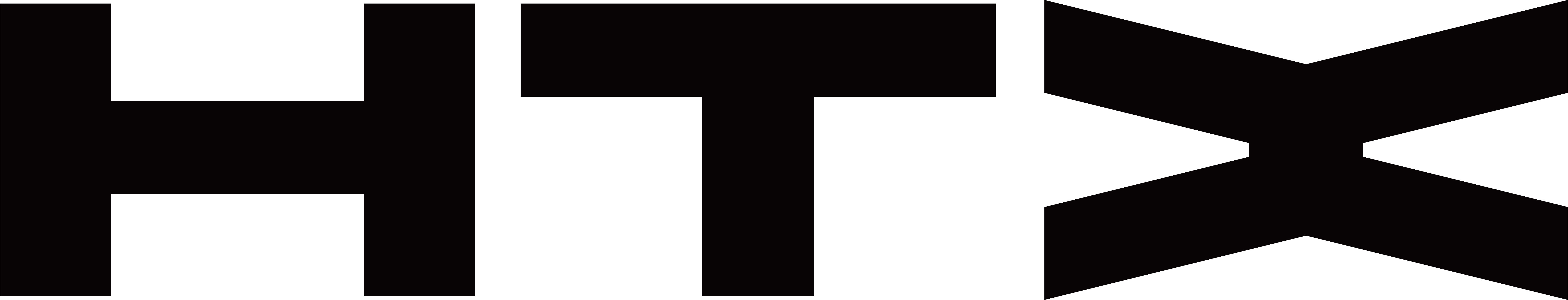

Process development and system integration for advanced powder-based technologies. Targeting emerging material applications.

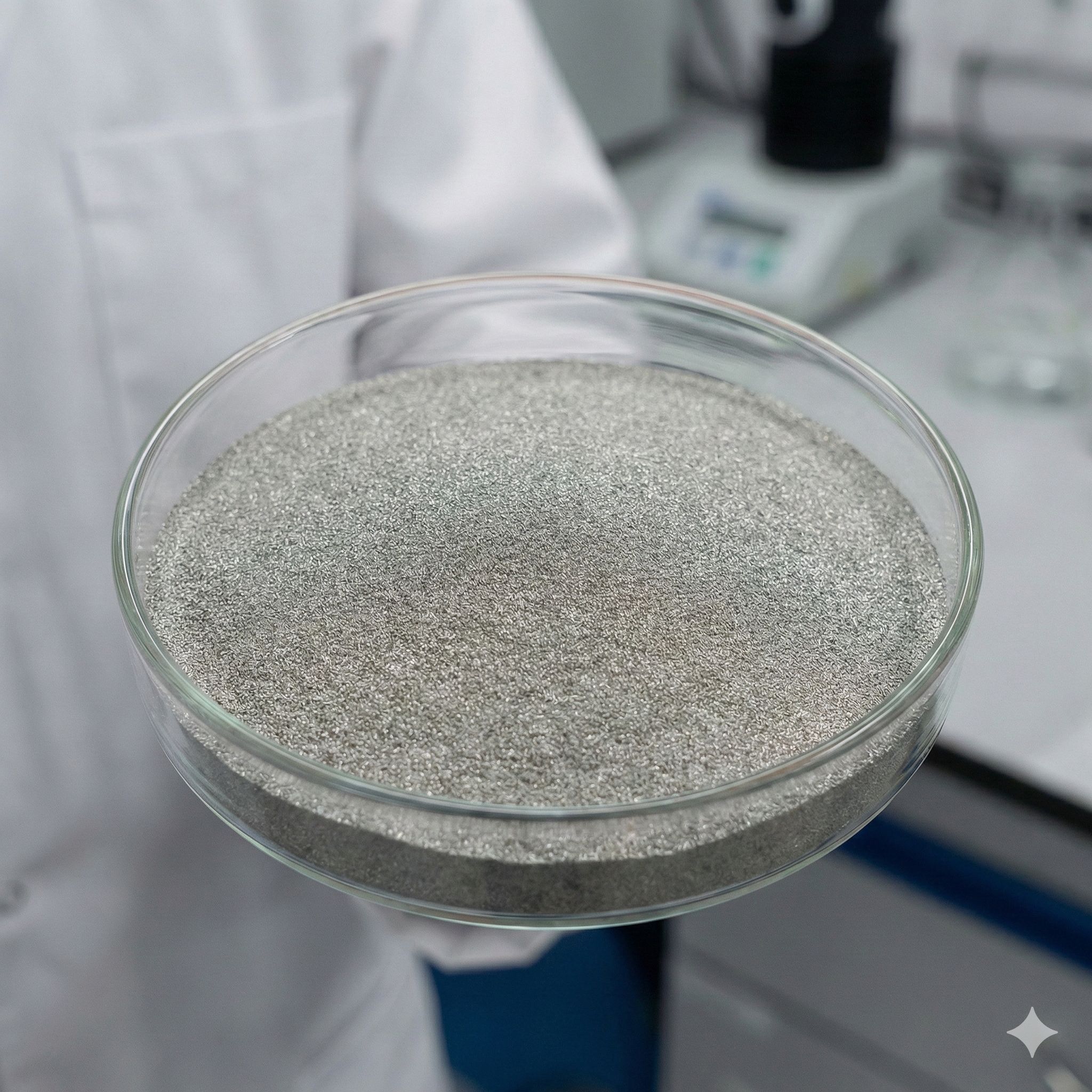

Robotic handling and system-level integration. Designed for repeatable operation and reduced manual intervention.

Engineering-driven ODM services with supply chain coordination for reliable production execution.

The systems presented here represent established process platforms.

Custom engineering requirements and broader integration scopes are handled through separate commercial discussions.