Standardized functional textile platforms designed to reduce heat penetration and manage radiant energy through surface-level reflection.

HTX Reflective Heat Shielding materials are standardized functional textile platforms defined at the material level. They are designed to reduce heat penetration and manage radiant energy through surface-level reflection, rather than relying on thick insulation layers or opaque structures.

By applying a reflective, metal-based surface functional architecture onto lightweight textile substrates, these materials help limit heat transfer caused by direct sunlight exposure.

The result is a cooler internal environment while maintaining light transmission control, flexibility, and fabric usability. This material platform is suitable for both wearable and architectural applications, integrating into existing textile designs without altering form, drape, or installation systems.

HTX Reflective Heat Shielding materials are offered as standardized material platforms, with functional performance defined at the material surface level.

The platform can be applied to various base fabrics, including mesh and perforated textile structures, allowing controlled light transmission while reflecting radiant heat.

Materials may be produced on HTX internal processing lines or by qualified manufacturing partners under controlled conditions. They are designed for direct integration into existing production workflows without requiring additional equipment or structural redesign.

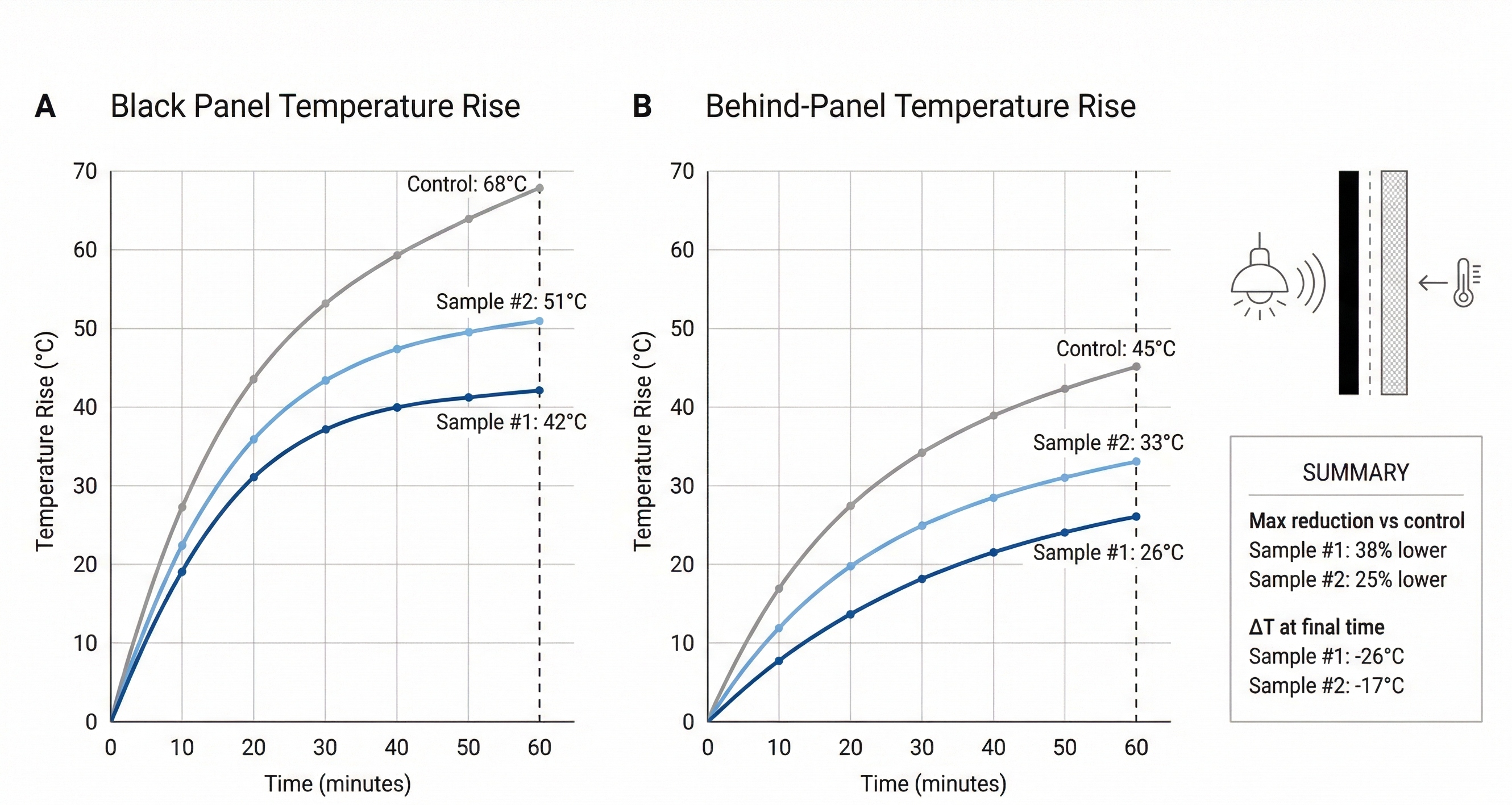

The heat shielding behavior of HTX Reflective materials has been evaluated using standardized testing methods commonly applied to automotive curtain systems.

Testing compares the temperature rise over time between an untreated control sample and an HTX-treated reflective material under controlled radiant heat exposure.

| Sample | Temp (°C) | Performance |

|---|---|---|

| Untreated Control | 68°C | Baseline |

| HTX-Treated (Sample #1) | 42°C | -26°C Reduction |

| HTX-Treated (Sample #2) | 51°C | -17°C Reduction |

Result: The HTX-treated sample demonstrates significantly lower heat absorption, achieving a temperature reduction of up to 38% compared to the control fabric.

HTX-13 represents a reflective, metal-based surface functional architecture designed for radiant heat control and solar shielding applications.

For reflective heat shielding material platforms, HTX provides optional material identification tools to support consistent downstream communication.

The identification tag does not function as branding or certification. It serves as a material reference, enabling brands and system integrators to explain material-level functionality without disclosing proprietary process details.

Material identification tools are optional and application-specific. They are intended to support transparency and material education without affecting brand identity or marketing language.

We welcome discussions to evaluate material suitability for your specific application.

Email HTX MaterialsIf possible, please include: