Material Overview

HTX Warmth & Thermal Comfort materials are standardized functional textile platforms defined at the material level. They are designed to enhance perceived thermal comfort during wear, without relying on bulky insulation or heavy structural layers.

Through a titanium-alloy-based surface functional architecture, these materials help reduce unnecessary heat loss during daily wear and low-activity conditions, while maintaining overall comfort and thermal stability. The material platform integrates seamlessly into existing fabric designs without altering garment silhouette, appearance, or pattern structure.

Key Material Characteristics

- Material-level support for warmth and thermal comfort

- Titanium-alloy-based surface functional architecture

- Maintains original breathability, softness, and stretch behavior

- Does not rely on thick padding or structural insulation layers

- Suitable for long-duration wear, rest, and recovery-oriented applications

Typical Applications

Outerwear & Light Jackets

- Lightweight jackets

- Transitional-season outer layers

- Daily garments for users sensitive to cooler environments

Innerwear & Home Wear

- Close-to-skin inner layers

- Home wear

- Sleepwear designed for comfort and thermal stability

Recovery-Oriented Apparel

- Rest and relaxation garments

- Low-activity comfort wear

- Apparel designed for warmth during recovery or downtime

Final garment design and application methods are defined by downstream partners.

Material Platform & Supply

HTX Warmth & Thermal Comfort materials are offered as standardized material platforms, with functional behavior defined at the material surface level.

Materials may be produced on HTX internal lines or by qualified manufacturing partners under controlled process conditions. They are designed for direct integration into existing apparel manufacturing workflows without requiring additional equipment or structural changes.

Thermal Comfort Design Positioning

This material platform is not designed to block airflow or increase garment thickness. Instead, it supports thermal stability by managing surface-level heat behavior, contributing to a warmer yet lightweight wearing experience.

This allows garments to remain comfortable during both active and static conditions, making them suitable for extended wear, rest, and recovery scenarios.

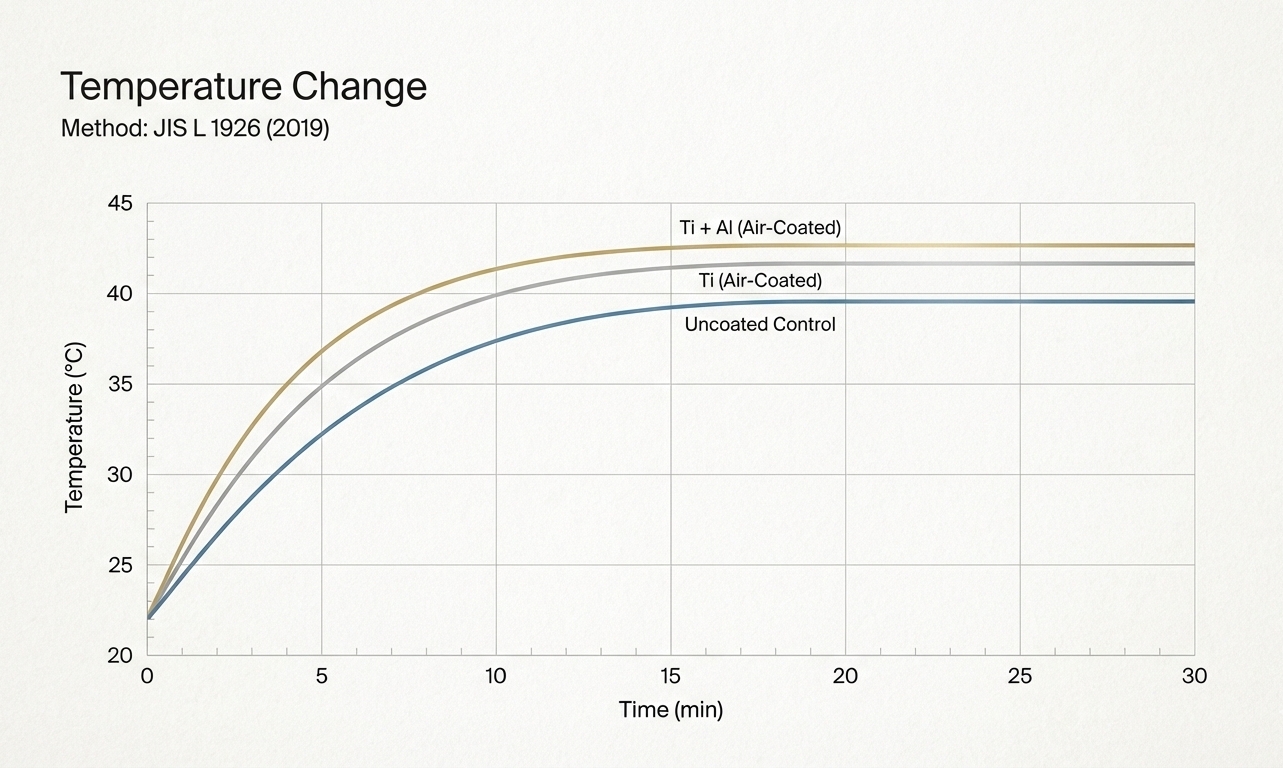

Photothermal Performance

Test Method: JIS L 1926 (2019)

Under controlled light exposure, Air-Coated variants demonstrate higher temperature rise compared to untreated control materials.

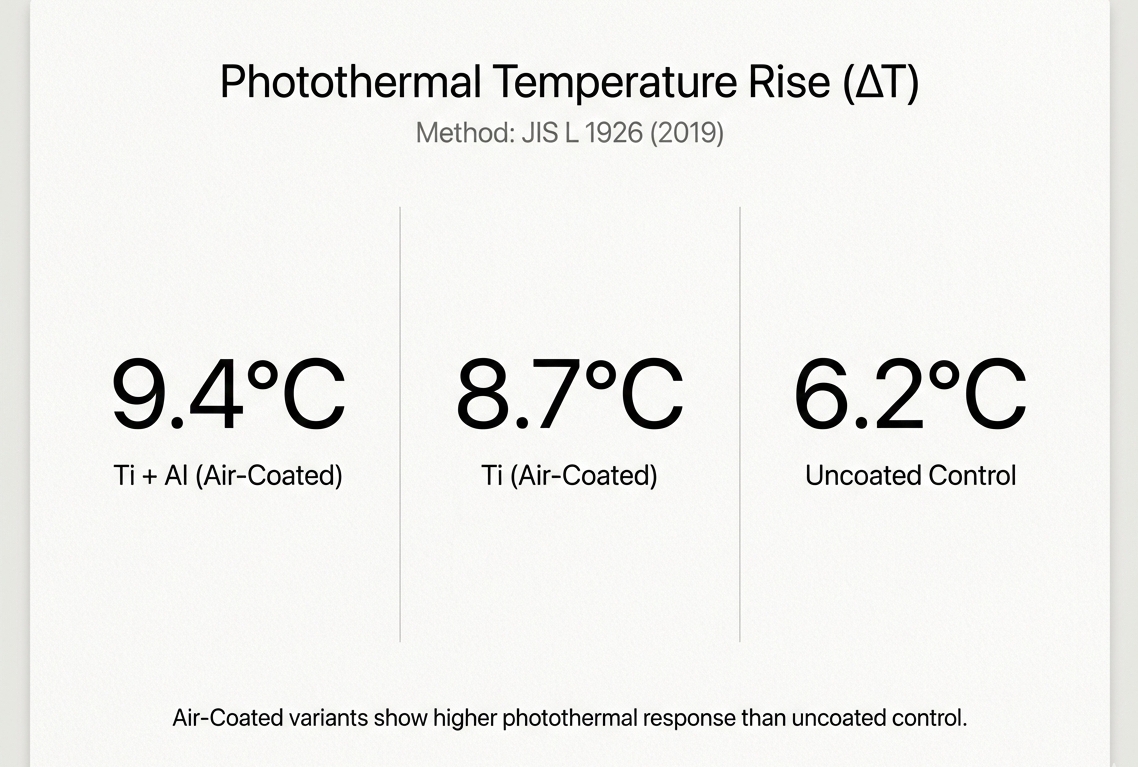

Photothermal Temperature Rise (ΔT)

| Variant | Temp Rise (ΔT) |

|---|---|

| Ti + Al (Air-Coated) | 9.4°C |

| Ti (Air-Coated) | 8.7°C |

| Uncoated Control | 6.2°C |

Material Identification for Warmth & Recovery

HTX-22 represents a titanium-alloy-based functional surface architecture designed for thermal comfort applications.

For warmth and recovery-oriented material platforms, HTX provides optional material identification tools to support consistent downstream communication.

The identification tag does not function as branding or certification. It serves as a material reference, enabling brands to explain material-level functionality without disclosing proprietary process details.

Identification Formats Available

- HTX Standard Hangtag: Provided upon request, including the HTX material reference code (e.g. HTX-22).

- Co-Branded or Custom: Brands may incorporate the HTX material code within their own hangtag or communication system.

Start a Technical Discussion

We welcome discussions to evaluate material suitability for your specific application.

Email HTX MaterialsIf possible, please include:

- Target application (e.g. light jackets, innerwear, recovery apparel)

- Base fabric or yarn preferences

- Estimated volume or development stage

- Specific performance expectations (e.g. warmth retention, hand feel, stretch behavior)